How this Filta Franchisee Started her Thriving Business with $100K of her Retirement Savings

April 24, 2024

No Comments

Laid off from her role as an executive at a

Filta Ranks #266 in Entrepreneur Magazine’s Franchise 500

February 2, 2024

No Comments

As mentioned recently in Entrepreneur Magazine and RestaurantNews.com, Filta

Filta Franchisee Expanded from Northern Ohio to Pittsburgh and Plans to Double Revenue in Next Three Years

December 18, 2023

No Comments

Terry Walkerly has been a Filta franchisee for 16 years.

Filta Named to Franchise Times Top 400

November 28, 2023

No Comments

As was recently reported in the Franchise Times 400: Filta

Filta Offers a Repeat Customer Model to Franchisees

October 4, 2023

No Comments

One of the greatest advantages of owning a Filta Environmental

Filta Franchise Unique Development Approach: Standing Out from Competitors

August 17, 2021

No Comments

Even when servicing more than 10,000 restaurant and commercial kitchens

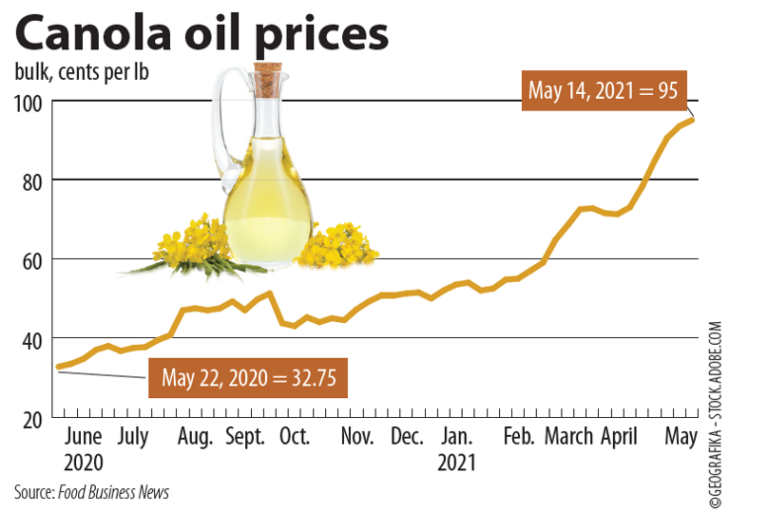

Your Solution for Savings in the Face of Doubled Cooking Oil Prices

August 10, 2021

No Comments

The price of vegetable oil has more than doubled since

Filta’s Next Priority Market for Franchise Expansion: Portland, Oregon

August 5, 2021

No Comments

Region is one of the few major US markets with

Five Important Reasons Filta Continues its Franchise Growth

August 3, 2021

No Comments

A franchise brand doesn’t reach its 25th year without a

Filta Kitchen Solutions Gears Up for Business Surge as Nationwide Lockdowns Lift

July 29, 2021

No Comments

Filta and its nationwide network of about 150 franchise owners

How to Start a Family Franchise Restaurant Business Without Experience

April 25, 2021

No Comments

If you’re wondering how to start a family franchise business,

Why Explore Our Green Business Franchise Opportunities?

April 18, 2021

No Comments

Filta’s green business franchise opportunities aren’t just great investments; they’re